GBC Laminator Instructions: A Comprehensive Guide (Updated 12/12/2025)

This guide provides detailed instructions for GBC laminators, referencing manualsbase resources from August 20, 2020, and offering comprehensive support for users today․

Understanding your GBC laminator’s capabilities and following these instructions ensures optimal performance and longevity, safeguarding your valuable documents with professional results․

GBC laminators are widely recognized as a leading solution for document protection and enhancement, offering a range of machines for both home and professional use․ These laminators encapsulate documents within a clear plastic film, shielding them from everyday wear and tear, including moisture, dust, and handling damage․

From preserving important photographs and certificates to creating durable signage and ID cards, GBC laminators provide a versatile and cost-effective method for extending the lifespan of your valuable papers․ The availability of user manuals, such as those found on manualsbase (added August 20, 2020), demonstrates GBC’s commitment to supporting its customers with accessible information․

This comprehensive guide, updated as of December 12, 2025, aims to provide a thorough understanding of GBC laminator operation, maintenance, and troubleshooting, ensuring users can maximize the benefits of their laminating investment․

Types of GBC Laminators

GBC offers a diverse portfolio of laminators designed to cater to varying needs and volumes․ Primarily, these fall into two main categories: thermal laminators and cold laminators․ Thermal laminators utilize heat to melt the adhesive within the laminating pouch, creating a strong bond with the document․ These are ideal for frequent use and offer a professional, durable finish․

Cold laminators, conversely, employ pressure-sensitive adhesive pouches that do not require heat․ This makes them suitable for heat-sensitive materials like photographs or certain types of paper․ Resources like manualsbase (referenced August 20, 2020) often detail the specifications of each model, helping users determine the best fit․

Within these categories, GBC laminators vary in features such as warm-up time, maximum pouch size, and adjustable temperature settings, allowing for customization based on specific laminating requirements․

Thermal Laminators

Thermal GBC laminators represent the most common choice for general laminating tasks, utilizing heat to fuse the pouch to your document․ These machines feature heated rollers that activate the adhesive within the laminating pouch, creating a durable, professional finish․ Warm-up times vary by model, but typically range from a few minutes to around five․

Temperature control is a key feature, allowing adjustment for different pouch thicknesses (3mil, 5mil, 7mil – details covered elsewhere)․ Proper temperature settings are crucial to avoid wrinkles or bubbles; GBC manuals, like those found on manualsbase (dated August 20, 2020), emphasize the importance of allowing the laminator to fully heat before use․

Thermal laminators are well-suited for high-volume laminating and provide excellent protection against damage, making them ideal for frequently handled documents․

Cold Laminators

Unlike thermal laminators, GBC cold laminators utilize pressure-sensitive adhesive pouches, requiring no heat for the laminating process․ This makes them ideal for materials sensitive to heat, such as photographs, certain types of paper, or items with heat-sensitive inks․ Cold lamination relies on the firm pressure applied by the rollers to bond the pouch to the document․

While they don’t require warm-up time, cold laminators often require more physical effort to operate, as you need to feed the pouch through the machine with consistent pressure․ GBC resources, including manuals available on platforms like manualsbase (as of August 20, 2020), highlight the importance of even pressure distribution․

Cold lamination is excellent for wide-format prints and applications where heat could cause warping or discoloration․

Safety Precautions

Operating a GBC laminator requires adherence to crucial safety guidelines to prevent injury and ensure the longevity of the machine․ Always disconnect the laminator from the power source before performing any maintenance or cleaning procedures․ Never attempt to disassemble or repair the laminator yourself; refer to qualified technicians for complex issues․

Be mindful of the hot surfaces on thermal laminators during and immediately after use․ Allow sufficient cool-down time before handling or storing the device․ Avoid using the laminator in damp environments, and keep it away from flammable materials․ GBC manuals, like those found on manualsbase (dated August 20, 2020), emphasize these precautions․

Proper ventilation is also important, especially during prolonged use․

General Safety Guidelines

Prioritizing safety when using a GBC laminator is paramount for both the operator and the machine’s lifespan․ Always read and understand the complete user manual before initial operation, referencing resources like those available on manualsbase as of August 20, 2020․ Ensure the laminator is placed on a stable, level surface, away from edges where it could fall․

Keep the surrounding area clear of obstructions and flammable materials․ Never insert anything other than approved laminating pouches into the machine․ Supervise children and inexperienced users closely when the laminator is in operation․ Regularly inspect the power cord for damage and replace it if necessary․

Avoid forcing pouches through the machine; this can cause jams and potential damage․

Avoiding Burns & Electrical Hazards

GBC laminators reach high temperatures during operation, presenting burn risks․ Never touch the heated rollers or exterior surfaces while the machine is on or immediately after use; allow sufficient cool-down time․ Exercise extreme caution when handling laminated pouches as they will also be hot․ Always use the provided carrier sheet or gloves when removing hot pouches․

To prevent electrical hazards, ensure the laminator is properly grounded and connected to a compatible power outlet․ Never operate the machine with a damaged power cord or plug․ Do not attempt to disassemble or repair the laminator yourself; refer to qualified service personnel․ Keep liquids away from the machine to avoid short circuits and electrical shock․ Refer to manualsbase (August 20, 2020) for detailed safety information․

Understanding Laminating Pouches

Laminating pouches are essential for protecting documents, and selecting the right pouch is crucial․ They consist of a polyester film bonded to a layer of adhesive, activated by heat or pressure․ Pouches come in various sizes to accommodate different document dimensions, ensuring complete coverage․ Compatibility with your GBC laminator is key; check the machine’s specifications for supported pouch sizes․

Understanding mil thickness is also vital – 3mil, 5mil, and 7mil pouches offer varying levels of rigidity and protection; Thicker pouches provide greater durability but may require higher temperature settings․ Referencing resources like manualsbase (August 20, 2020) can help determine the appropriate pouch for your needs, ensuring optimal lamination results and document preservation․

Pouch Sizes & Compatibility

GBC laminator pouches are available in a wide array of sizes, from business card to legal sheet dimensions, and beyond․ Common sizes include 9×11 inches, 8․5×11 inches, and 4×6 inches, catering to diverse document needs․ Crucially, compatibility hinges on your specific GBC model; always consult your laminator’s manual or online specifications․

Using incompatible pouch sizes can lead to jams, poor adhesion, or even damage to the machine․ Resources like manualsbase (referenced August 20, 2020) often detail compatible pouch types․ Ensure the pouch width aligns with your laminator’s throat opening․ Selecting the correct size guarantees a professional finish and prevents operational issues, maximizing the lifespan of both pouch and machine․

Mil Thickness Explained (3mil, 5mil, 7mil)

“Mil” refers to the thickness of the laminating pouch, measured in thousandths of an inch․ Understanding mil thickness is vital for selecting the appropriate pouch for your needs․ 3mil pouches offer basic protection, ideal for frequently handled documents like bookmarks or ID cards․ 5mil pouches provide a balance between durability and flexibility, suitable for posters and reports․

7mil pouches deliver the highest level of protection, perfect for items requiring significant wear and tear, such as menus or signage․ Heavier mil thicknesses may require higher laminator temperature settings․ Referencing resources like manualsbase (dated August 20, 2020) can clarify compatibility with your GBC model․ Choosing the correct mil ensures optimal lamination quality and longevity․

Setting Up Your GBC Laminator

Proper setup is crucial for successful lamination․ First, place your GBC laminator on a stable, flat surface with adequate ventilation․ Ensure the power cord is securely connected to a grounded outlet․ Before powering on, verify the laminator’s carrier release is unobstructed․ Consult manualsbase resources (August 20, 2020) for model-specific diagrams․

Next, select the appropriate laminating pouch based on your document size and desired thickness (refer to mil thickness guidelines)․ Allow sufficient space behind the laminator for the laminated document to exit freely․ Avoid placing the laminator near flammable materials․ Finally, familiarize yourself with the temperature control settings before proceeding to the warm-up phase․

Powering On & Warm-Up Time

Initiating your GBC laminator requires a specific sequence․ Press the power button; the indicator light will illuminate, signaling the warm-up cycle․ Refer to manualsbase documentation (dated August 20, 2020) for your model’s specific indicator light behavior․ Warm-up times vary depending on the laminator type and temperature setting, typically ranging from 3 to 5 minutes․

During warm-up, avoid obstructing the pouch feed area․ The laminator is not ready for use until it reaches the selected temperature, indicated by a change in the indicator light or an audible signal․ Prematurely attempting to laminate can result in poor adhesion or pouch jams․ Patience during this phase ensures optimal lamination quality and prevents potential damage to the machine․

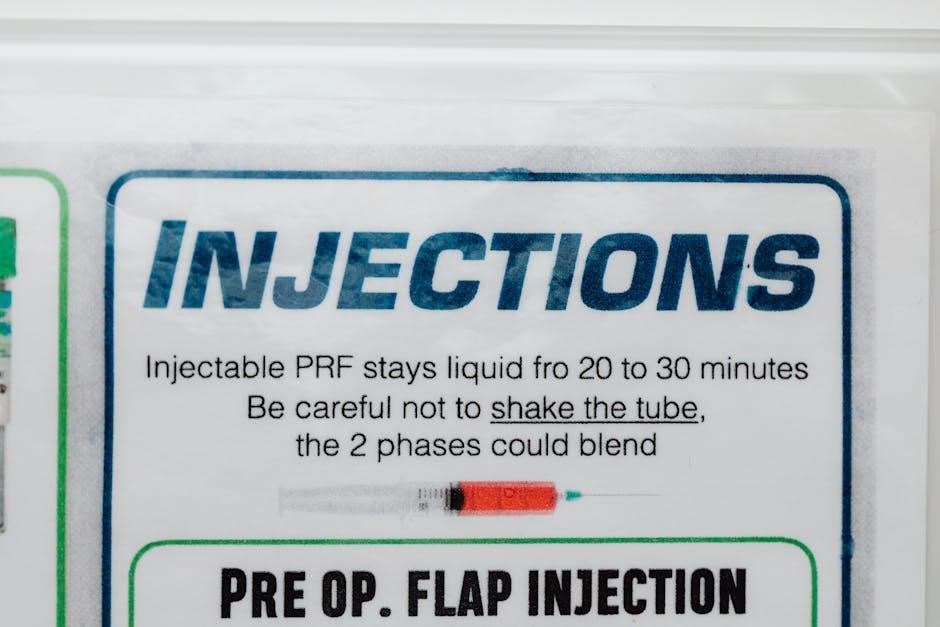

Temperature Settings – A Detailed Guide

GBC laminators typically offer multiple temperature settings, often indicated by numbers or pouch thickness recommendations․ Consult manualsbase resources (August 20, 2020) for your specific model’s temperature scale․ Lower settings (1-2) are ideal for 3mil pouches, providing a light protective coating․ Medium settings (3-4) suit 5mil pouches, offering increased durability for frequently handled documents․

Higher settings (5+) are reserved for 7mil pouches, delivering robust protection for items requiring significant wear and tear․ Incorrect temperature settings can lead to issues like wrinkling (too low) or pouch separation (too high)․ Always test with a sample pouch before laminating a large batch to confirm optimal settings for your chosen pouch thickness and material․

Laminating Process: Step-by-Step

Begin by ensuring your GBC laminator is fully warmed up, referencing the ‘Temperature Settings’ guide for appropriate heat levels․ Consult manualsbase resources (August 20, 2020) for model-specific warm-up times․ Carefully place your document within the laminating pouch, ensuring it’s centered with equal margins on all sides․

Insert the sealed edge of the pouch into the laminator first, allowing the machine to draw it through․ Do not force the pouch; let the rollers do the work․ As the pouch exits, it will be sealed and cooled․ Avoid touching the hot pouch immediately after lamination․ Once cooled, trim any excess lamination around the document’s edges for a professional finish․

Inserting the Pouch Correctly

Proper pouch insertion is crucial for successful lamination․ Always insert the pouch with the sealed edge entering the laminator first․ This prevents the pouch from opening mid-process and causing jams․ Refer to manualsbase documentation (dated August 20, 2020) for visual aids specific to your GBC model․

Ensure the pouch is fed straight into the machine; angling it can lead to wrinkles or misfeeds․ Never force the pouch through the laminator․ Allow the rollers to pull it through at their own pace․ If resistance is felt, stop immediately and consult the ‘Troubleshooting’ section․ Correct insertion guarantees a smooth, bubble-free lamination, protecting your documents effectively․

Troubleshooting Common Laminating Issues (Wrinkles, Bubbles)

Wrinkles and bubbles are common, but often preventable․ First, verify the pouch is inserted correctly – sealed edge first, straight alignment is key․ Consult manualsbase resources (August 20, 2020) for model-specific guidance․ If wrinkles persist, reduce the temperature setting slightly; excessive heat can cause pouch distortion․

Bubbles often indicate trapped air․ Ensure the document is completely flat before lamination․ For small bubbles, try gently pressing with a soft cloth immediately after exiting the laminator․ Avoid using sharp objects! If issues continue, check roller cleanliness – debris can cause imperfections․ Consistent troubleshooting leads to professional-quality results․

Dealing with Laminating Errors

Laminating errors happen, but quick action minimizes damage․ If a pouch jams (refer to the ‘Jammed Pouches’ section for safe removal), do not force it! Power off the laminator and allow it to cool completely before attempting extraction․ For misaligned laminations, carefully trim the excess laminate using a sharp paper cutter, ensuring straight edges․

If the document is severely damaged, unfortunately, re-lamination is usually necessary․ Prevention is key – always double-check pouch size and temperature settings․ Consult manualsbase (August 20, 2020) for specific error codes and solutions related to your GBC model․ Careful handling and prompt error management are crucial․

Jammed Pouches – Safe Removal Techniques

A jammed pouch requires immediate, careful attention․ First, and most importantly, power off and unplug the GBC laminator․ Allow sufficient cooling time – a hot laminator presents a burn risk․ Never attempt to pull a hot pouch; it will tear and adhere further․

Once cool, gently try to rock the pouch back and forth․ If it doesn’t budge, consult your model’s manual (resources available on manualsbase, dated August 20, 2020) for specific disassembly instructions․ Avoid using sharp objects that could damage the rollers․ Patience is vital; forcing the pouch can cause irreparable harm to the machine․ Proper maintenance reduces jamming frequency․

Misfeeds and How to Prevent Them

Misfeeds occur when the pouch doesn’t enter the laminator straightly, causing uneven lamination or jams․ Prevention begins with proper pouch alignment – ensure the sealed edge enters first․ Avoid using damaged or warped pouches; these are prone to misfeeds․ Regularly check the laminator’s rollers for debris or buildup, as this can impede smooth pouch travel․

If a misfeed happens, immediately power off and unplug the machine․ Gently attempt to realign the pouch, but avoid forcing it․ Refer to manualsbase resources (dated August 20, 2020) for model-specific guidance․ Consistent use of compatible pouch sizes and thicknesses minimizes misfeed occurrences, ensuring optimal performance․

Cleaning and Maintenance

Regular cleaning is crucial for maintaining your GBC laminator’s performance and extending its lifespan․ Always power off and unplug the machine before cleaning․ Use a soft, lint-free cloth to wipe down the exterior surfaces, avoiding abrasive cleaners․ The rollers require specific attention; gently clean them with a roller cleaner specifically designed for laminators, following the product’s instructions․

Referencing manualsbase documentation (August 20, 2020) provides model-specific cleaning recommendations․ Avoid getting any liquids inside the machine․ Consistent cleaning prevents pouch residue buildup, ensuring smooth operation and preventing potential jams․ Proper maintenance contributes to consistently high-quality lamination results․

Cleaning Rollers & Exterior Surfaces

Maintaining clean rollers is paramount for optimal lamination quality․ After each use, or regularly with frequent operation, gently wipe the rollers with a specialized laminator roller cleaner․ Avoid harsh chemicals or abrasive materials that could damage the roller surface․ For the exterior, unplug the laminator and use a soft, slightly damp (not wet!) cloth to wipe down the casing․

Dust and debris can accumulate, impacting performance․ Refer to manualsbase resources (dated August 20, 2020) for specific cleaner recommendations for your GBC model․ Ensure the laminator is completely dry before powering it back on․ A clean exterior not only improves appearance but also prevents dust from entering the internal components․

Long-Term Storage Instructions

Preparing your GBC laminator for extended storage requires careful attention to prevent damage and ensure future functionality․ First, ensure the laminator is completely cool and unplugged․ Clean the rollers and exterior surfaces as detailed in the maintenance section, removing any residual adhesive or debris․

Store the laminator in a dry, dust-free environment, ideally in its original packaging or a protective cover․ Avoid storing in areas with extreme temperatures or humidity․ Periodically (every 6-12 months), reconnect and briefly power on the laminator to circulate internal components․ Refer to manualsbase documentation (August 20, 2020) for model-specific storage advice, preserving your investment for years to come․